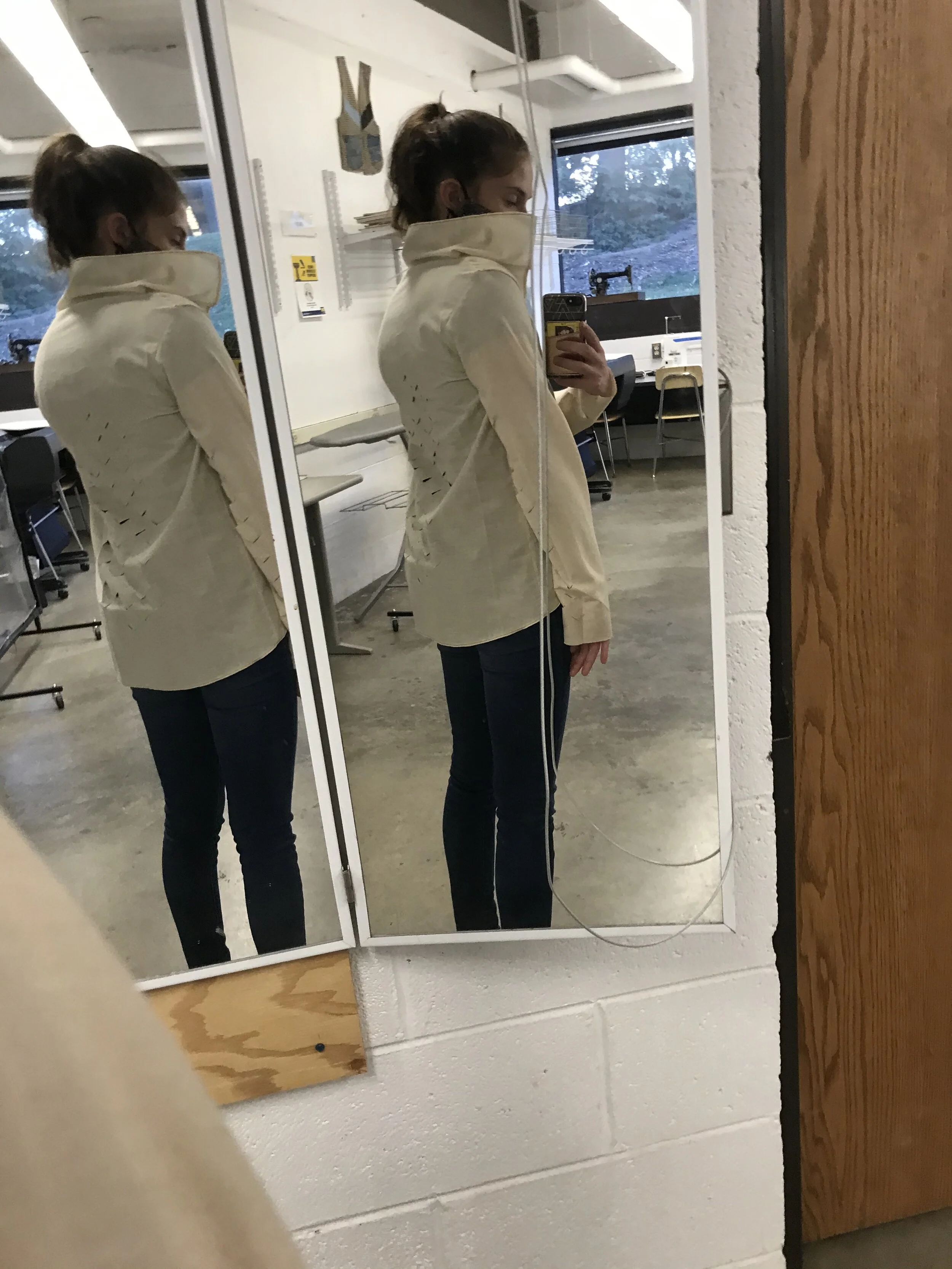

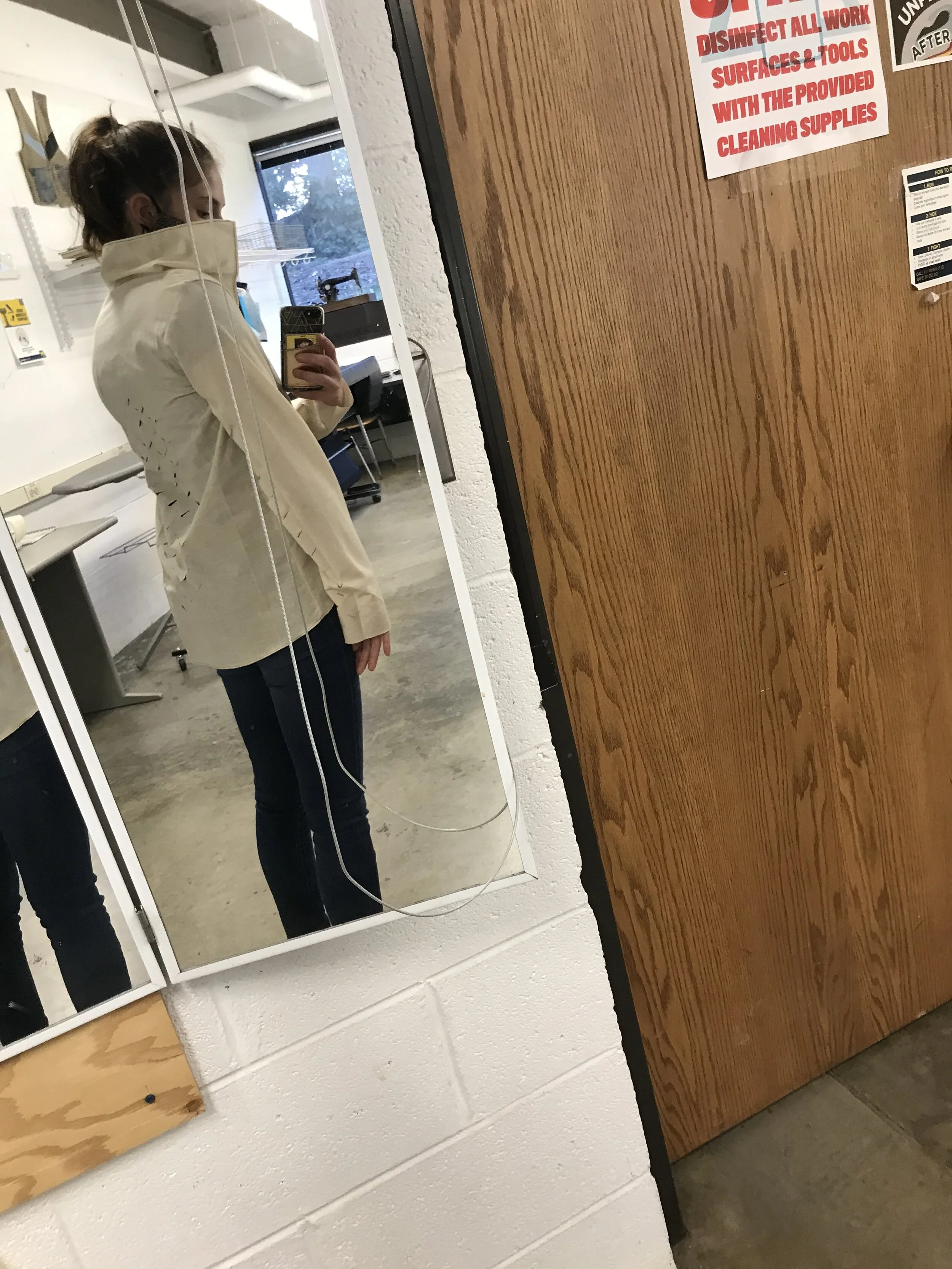

Paramount Jacket,

Fall 2020

Communicative Clothing

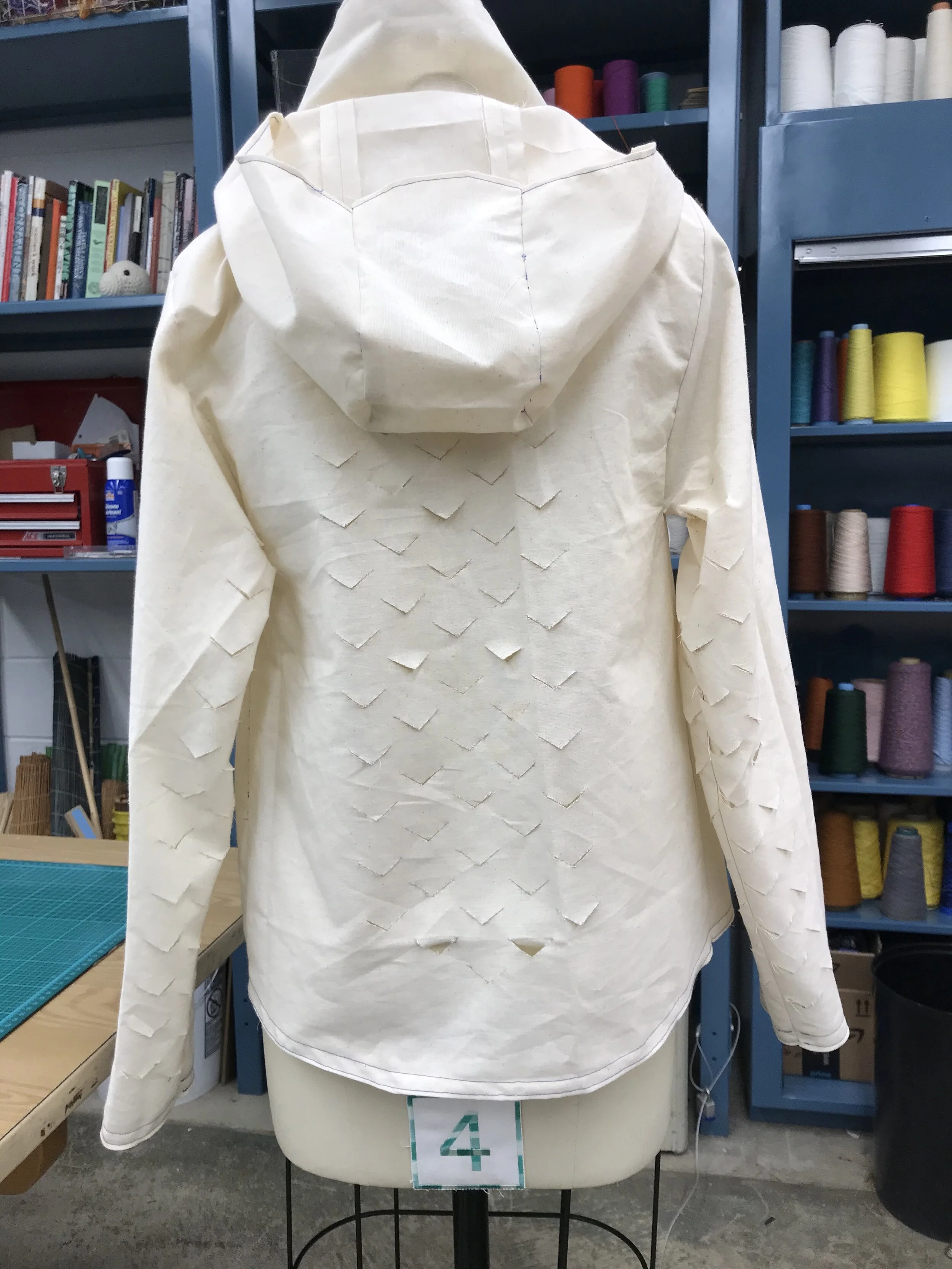

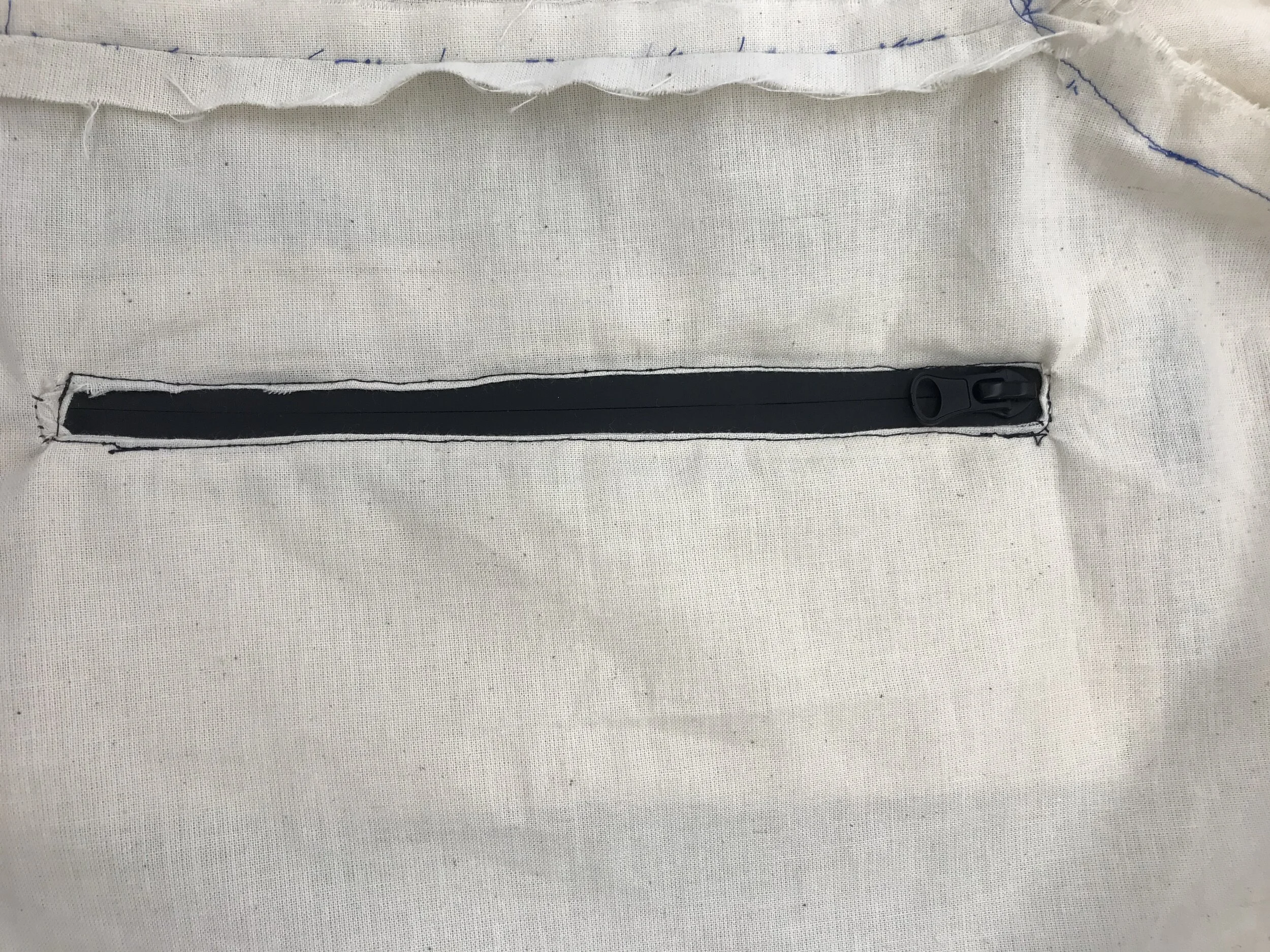

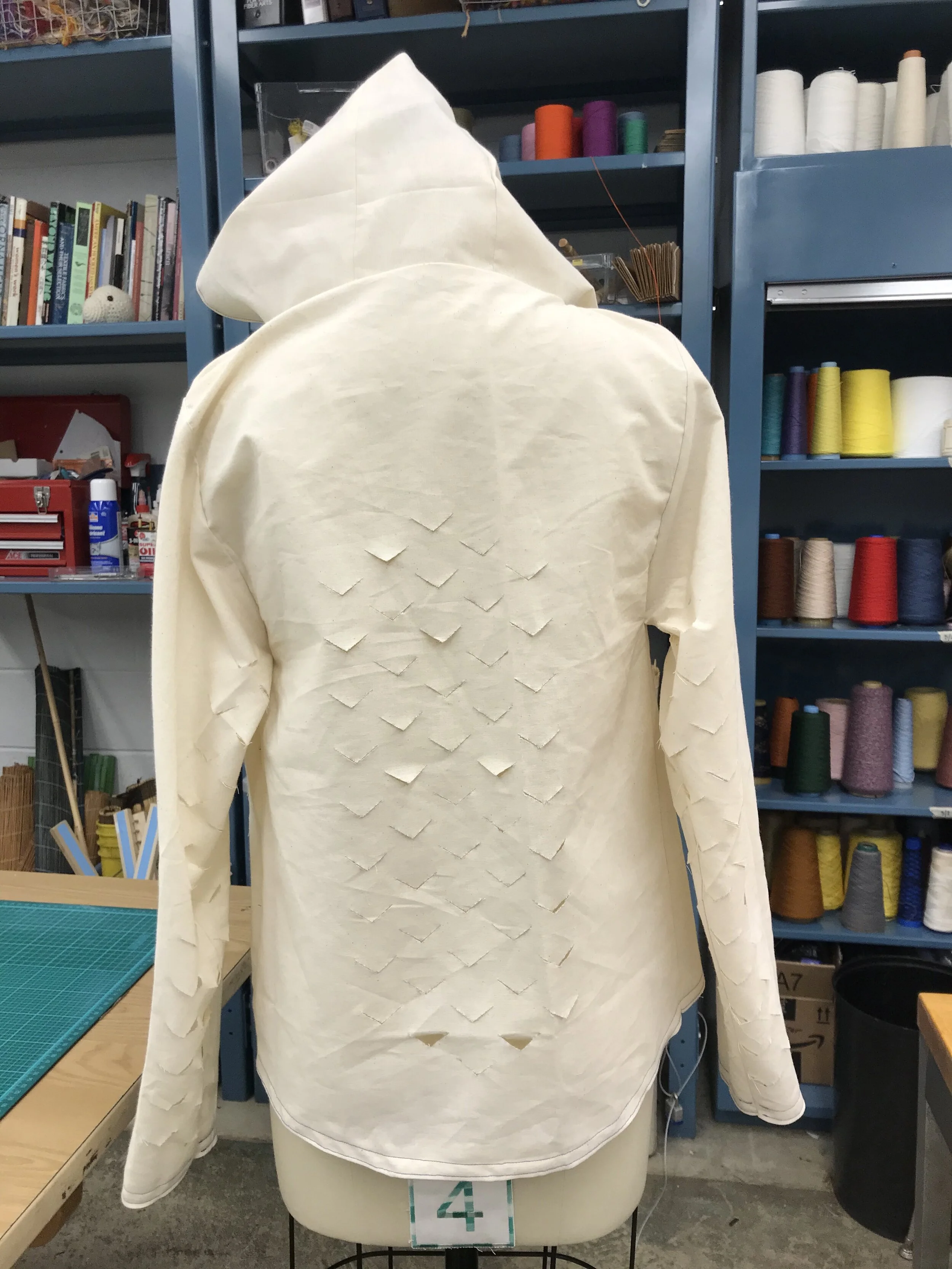

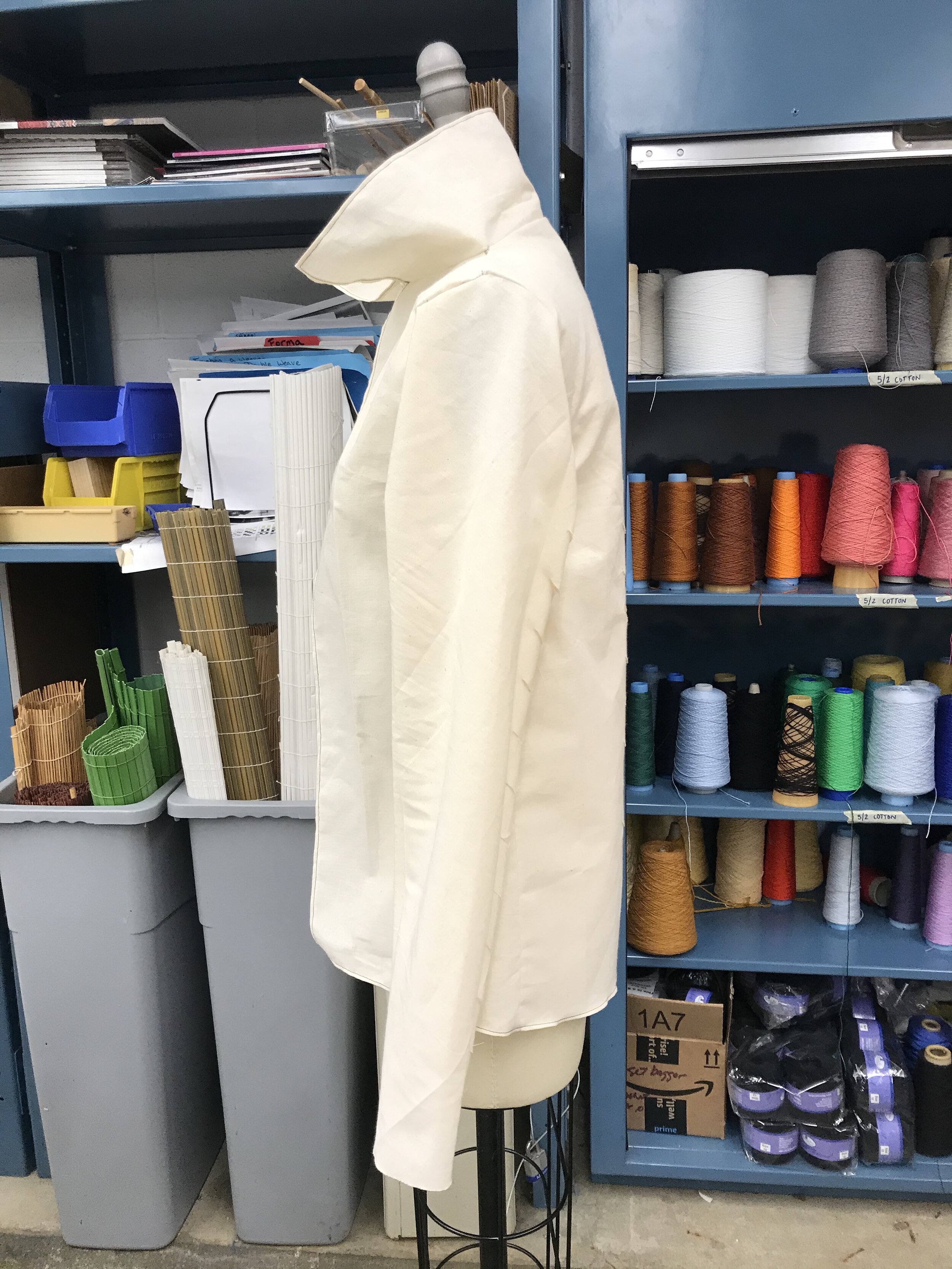

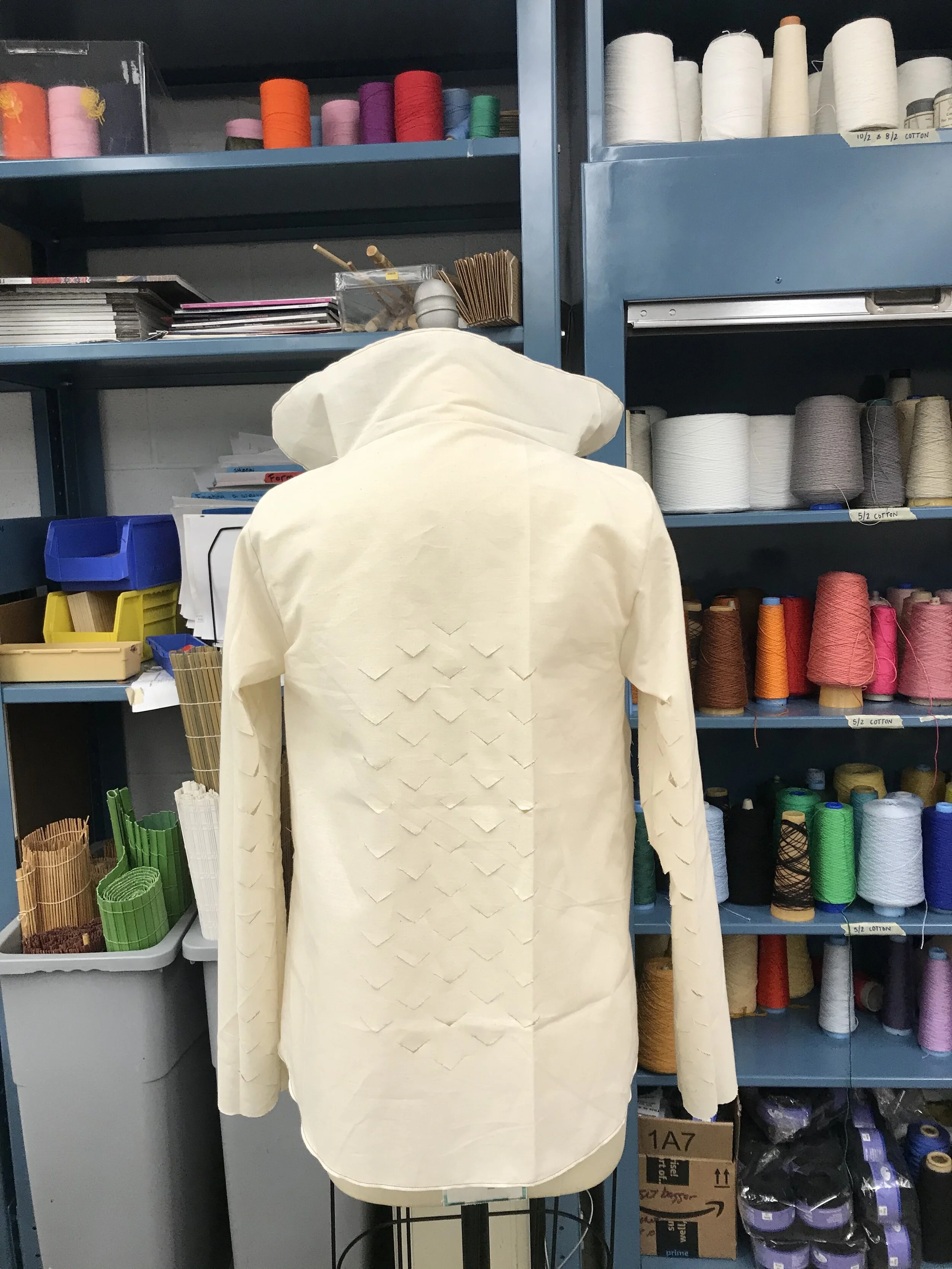

The Paramount jacket reverses the logic used for temperature control in outdoor clothing; instead of utilizing insulation to provide warmth, the Paramount jacket uses strategically-placed vents to dump heat during exertive activity. These magnetically-secured vents are controlled by a heart-rate monitor that is embedded in the left sleeve cuff. A sudden and or significant increase in the user’s heart rate will reverse the polarity of the petals’ magnets, causing the otherwise attracted pairs to repel one another; opening the petals, and revealing their bright teal linings. A subsequent decrease in heart rate will similarly cause the magnets’ polarity to be reversed; closing the petals, and restoring the jacket’s all-black appearance. Within the context of sport climbing, this action additionally acts as a warning to the belayer that the climber is at an increased risk of falling—as increased heart rate correlates with forearm pump, general fatigue, and the execution of risky moves.

*I had no prior sewing/pattern drafting experience before tackling this project

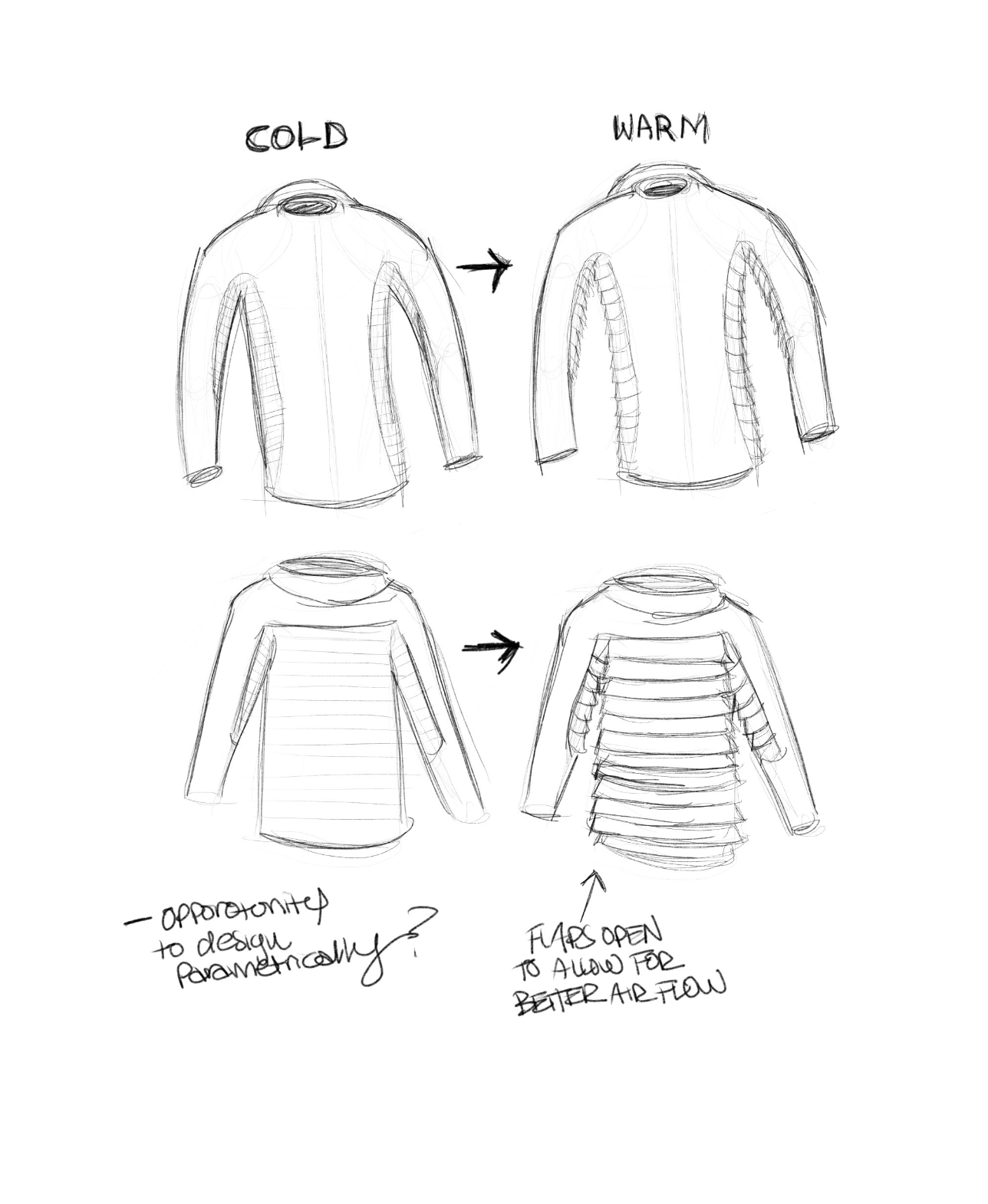

Ideation

After settling on a project concept, I created a mood board of jackets that best reflected my target audience of outdoor enthusiasts. I referenced this while drafting rough concept sketches to determine how the coat's functionality would influence aesthetics. It was integral to this product concept that form and function went hand-in-hand, as the climber’s safety relied on the jacket visually communicating safety information to their belayer.

Research

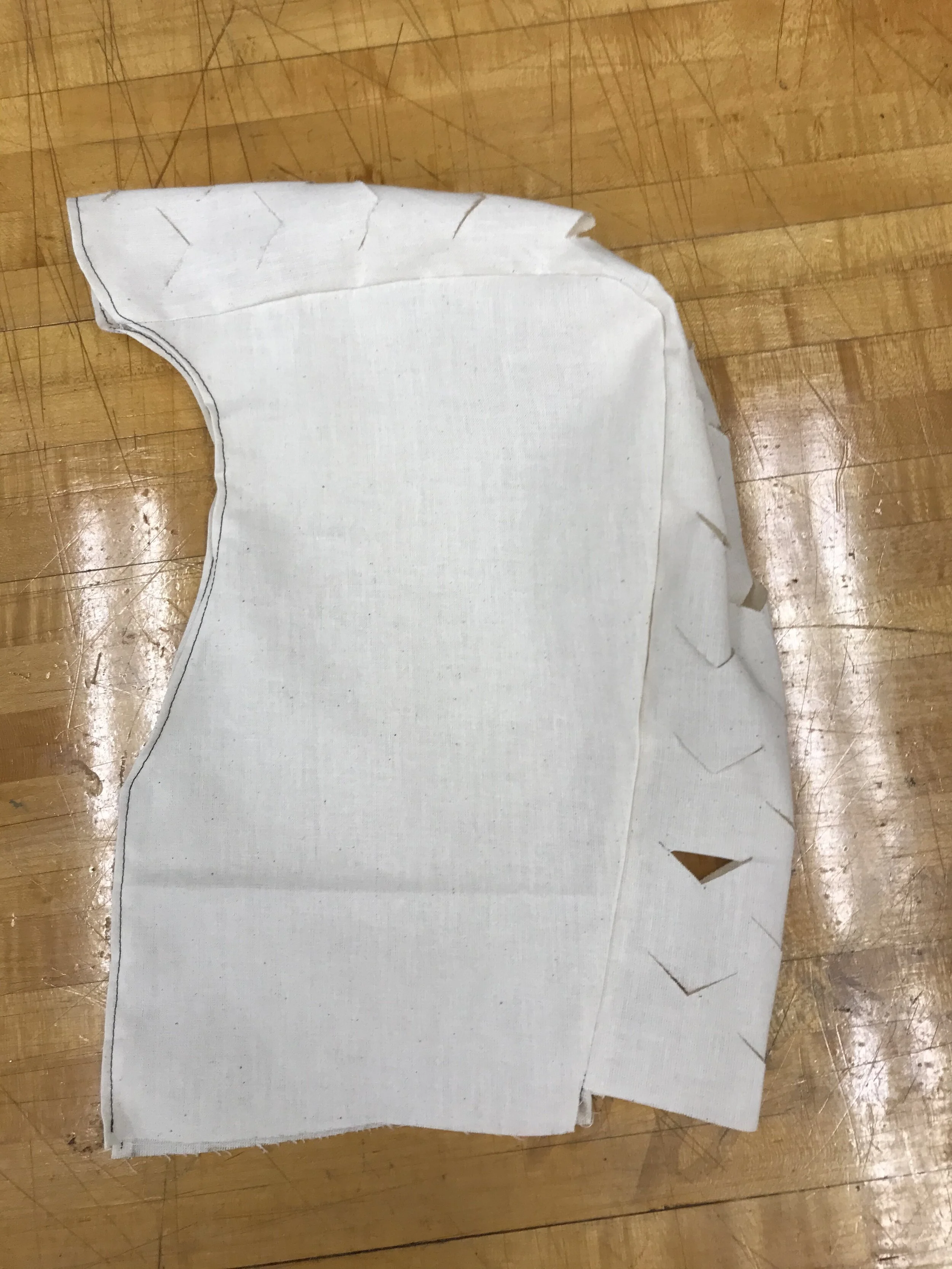

I decided to disassemble a Columbia jacket to get a better understanding of modern rain shell construction and how complex patterns translate into cohesive products. To deconstruct the jacket, I utilized a razor blade and a seam ripper to delaminate and detach all of the hems and seams. Once I had all of the components separated and sorted, I took overhead photos and registration measurements of each part in order to recreate the pattern in Fusion 360. This process kickstarted my materials research, as it allowed me to analyze the relationships and functions of the various materials that made up this jacket, which gave me a point of reference for investigating industry alternatives. This process also allowed me to familiarize myself with the process of pattern drafting.

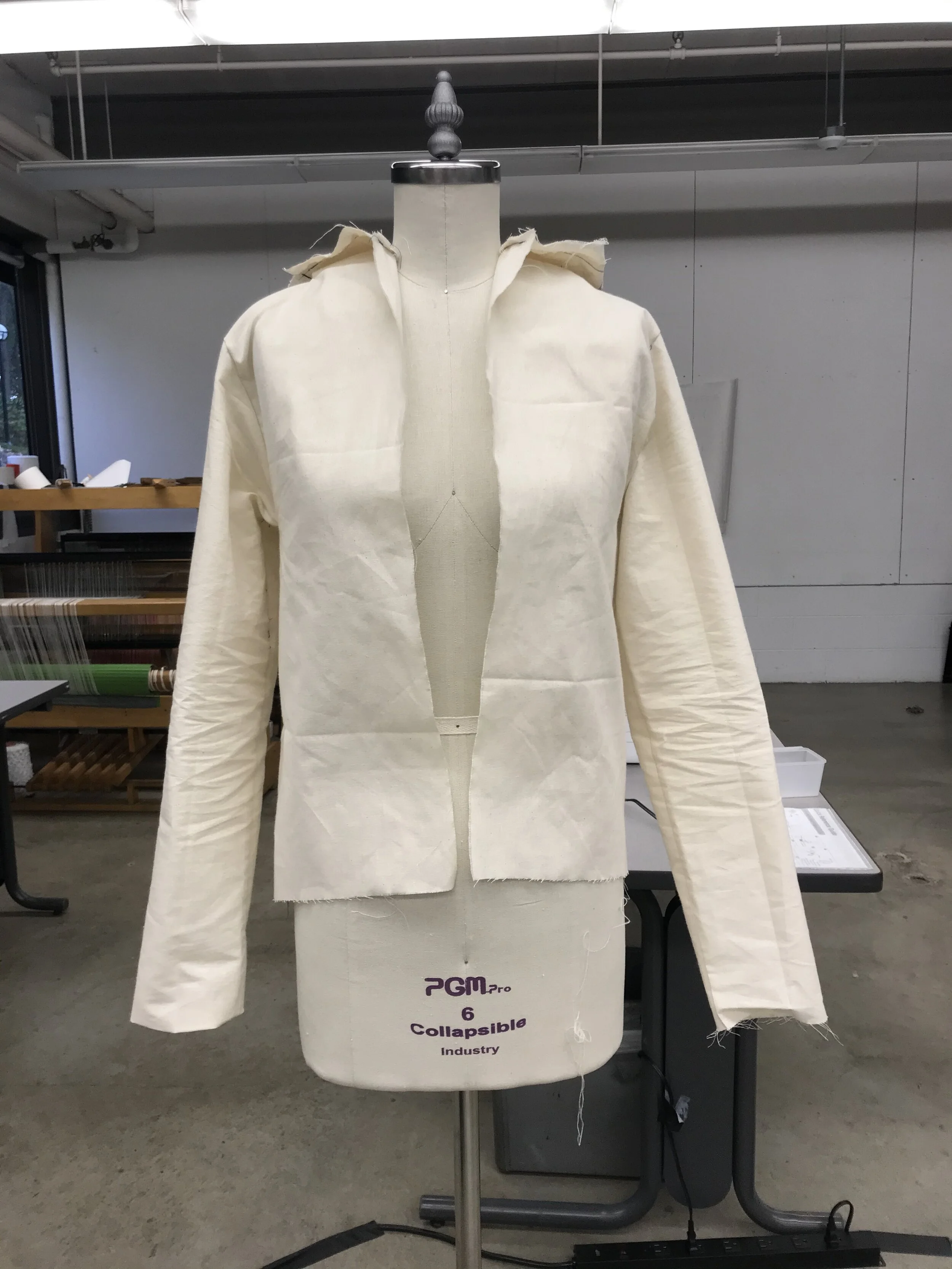

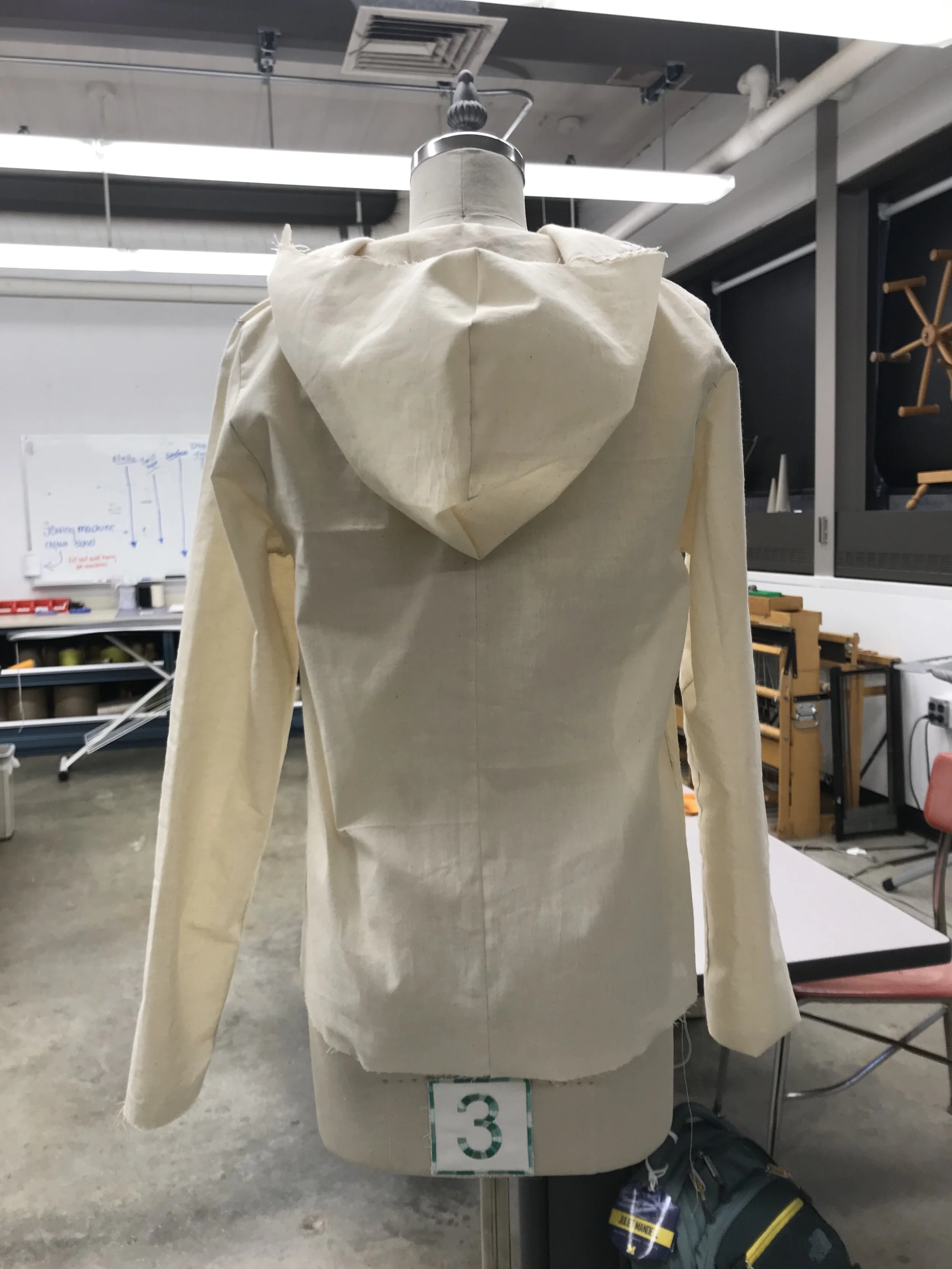

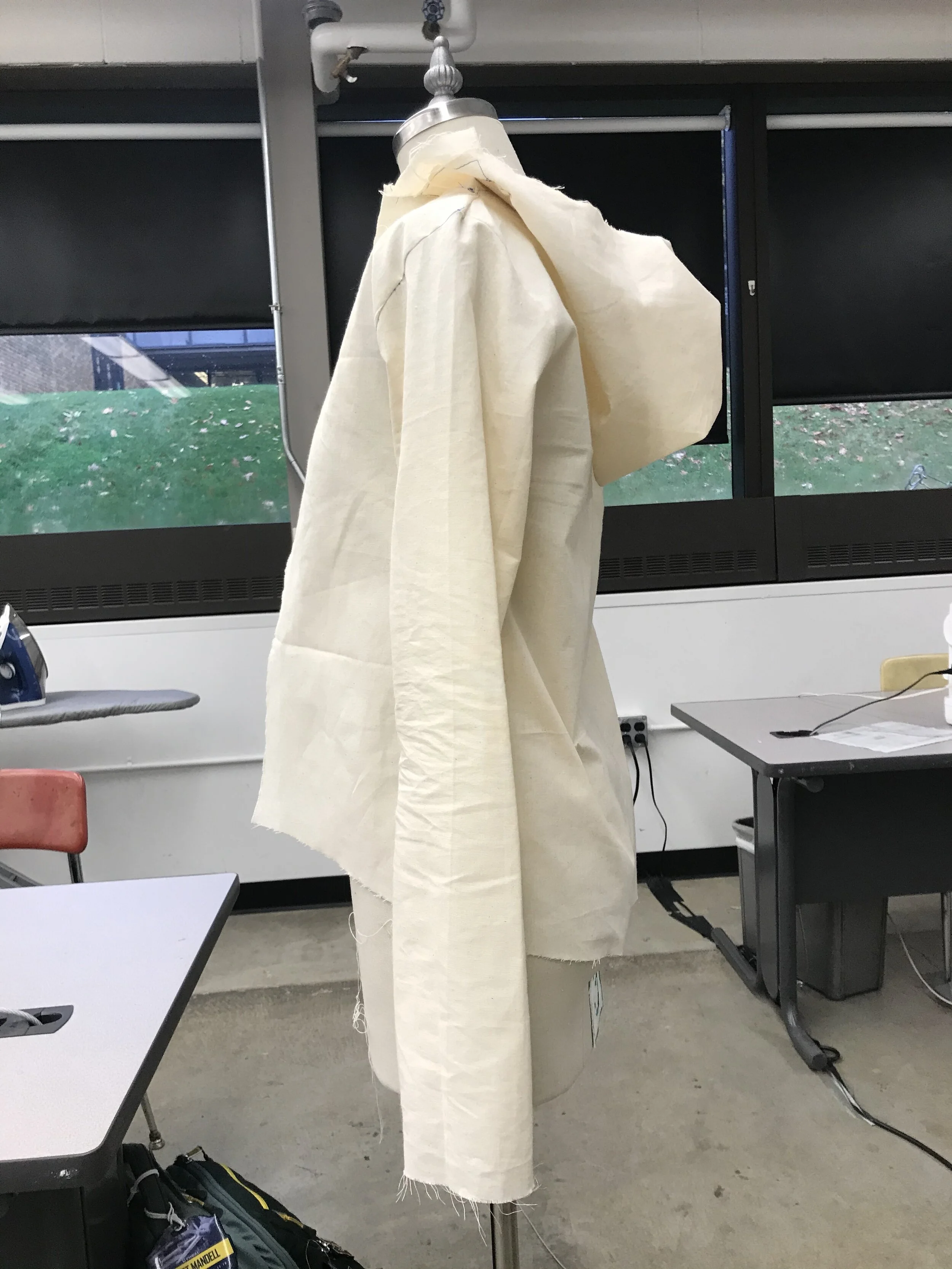

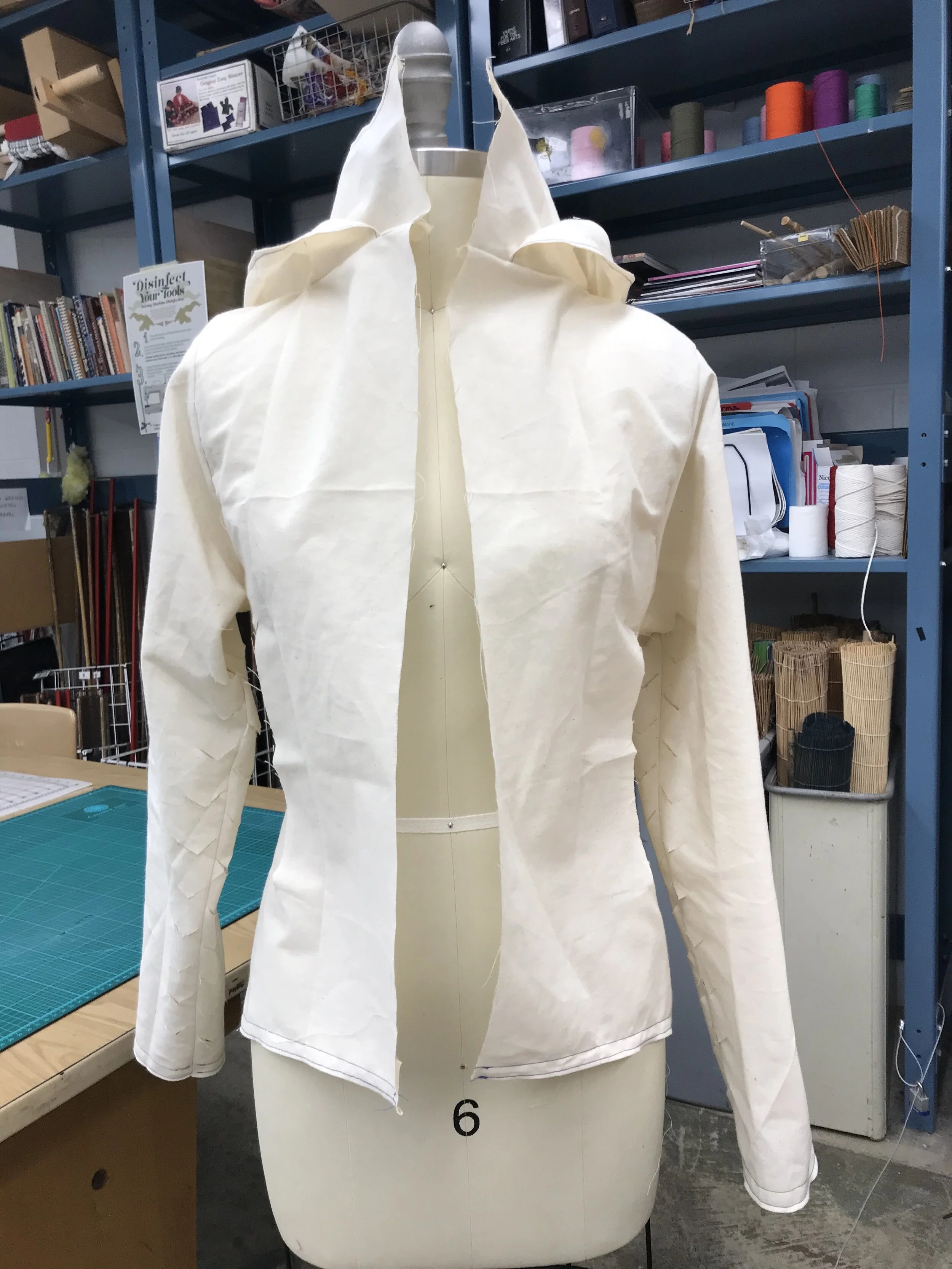

Iteration

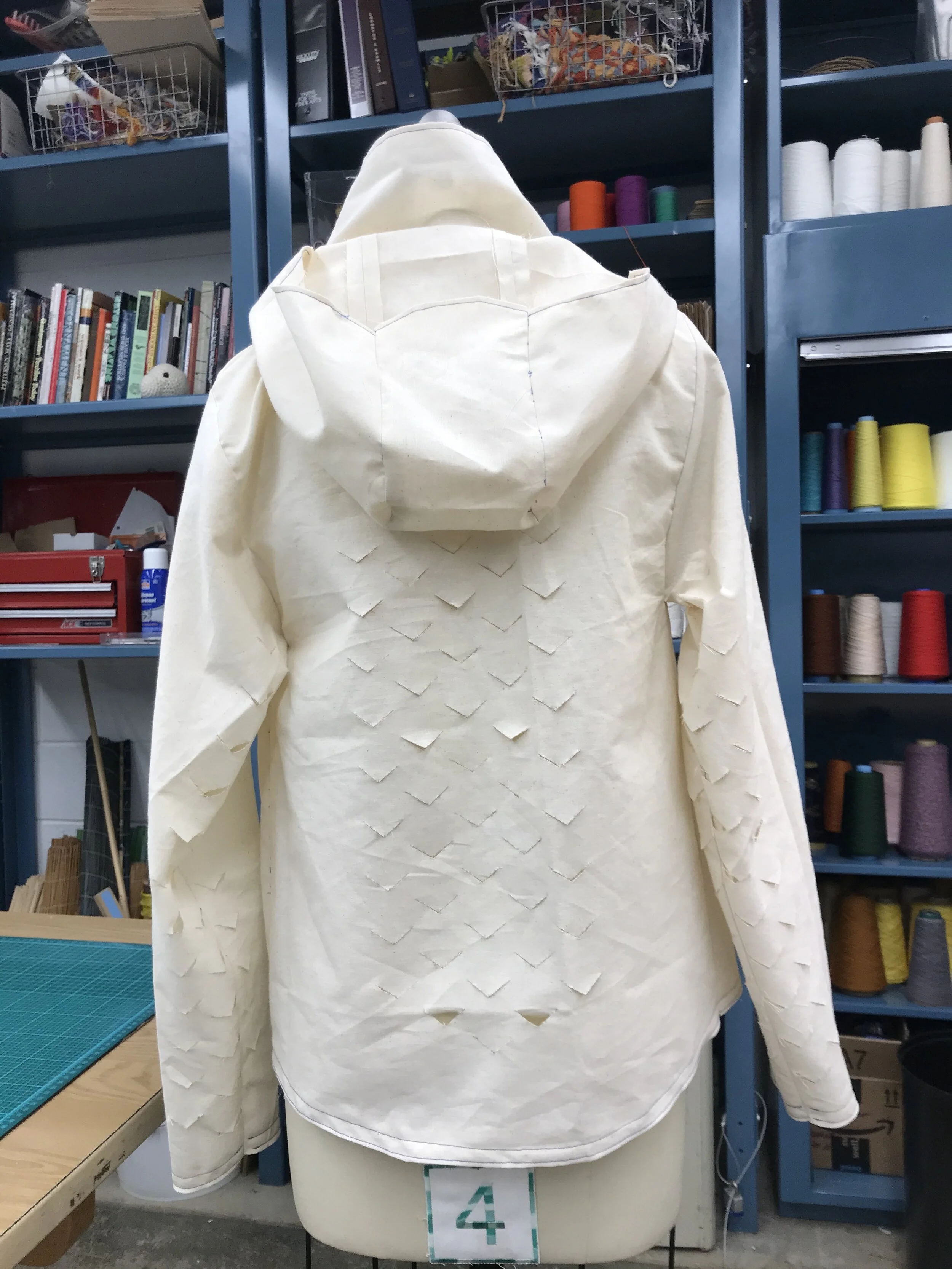

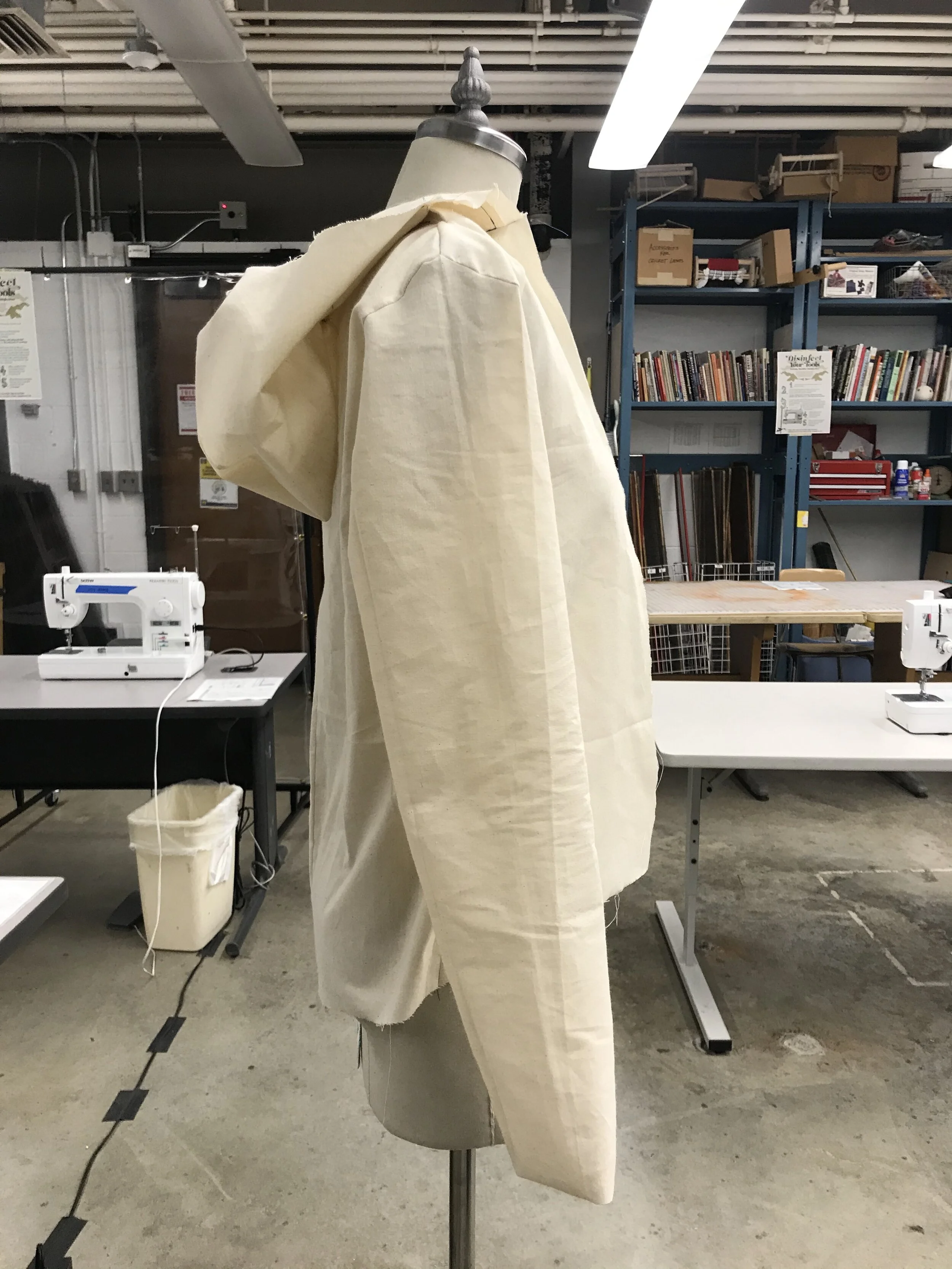

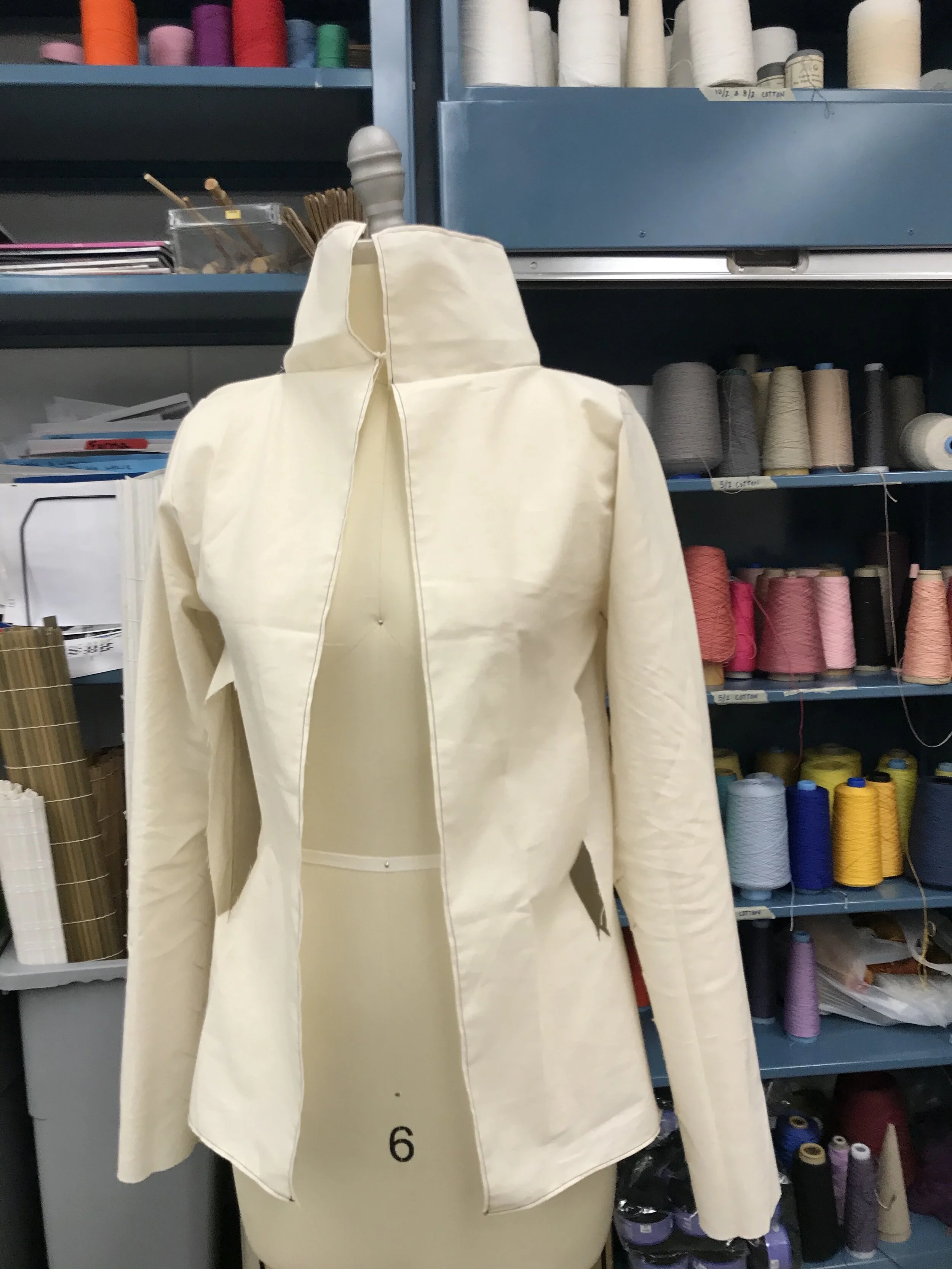

I began pattern drafting by taking measurements from my rain shell and roughly outlining its profile on a large sheet of construction paper. Then, I took overhead photographs of the sketches I had made, and refined the linework in Fusion 360, just as I did in my research phase. Once I had developed a digital pattern, I began the prototyping process: This consisted of laser-cutting my components in muslin, and sewing together prototypes to check for fit until I achieved a comfortable and visually appealing design. Using the final muslin prototype for reference, I finished my project by making a “Looks Like" prototype of the Paramount Jacket from rip-stop nylon.